These will fuse with the molten metal when the casting is poured. Should extra support for the cores be required, chaplets or spacers are properly positioned to maintain the required dimension. Cores are located in pockets formed by projections on the pattern equipment to produce core prints.

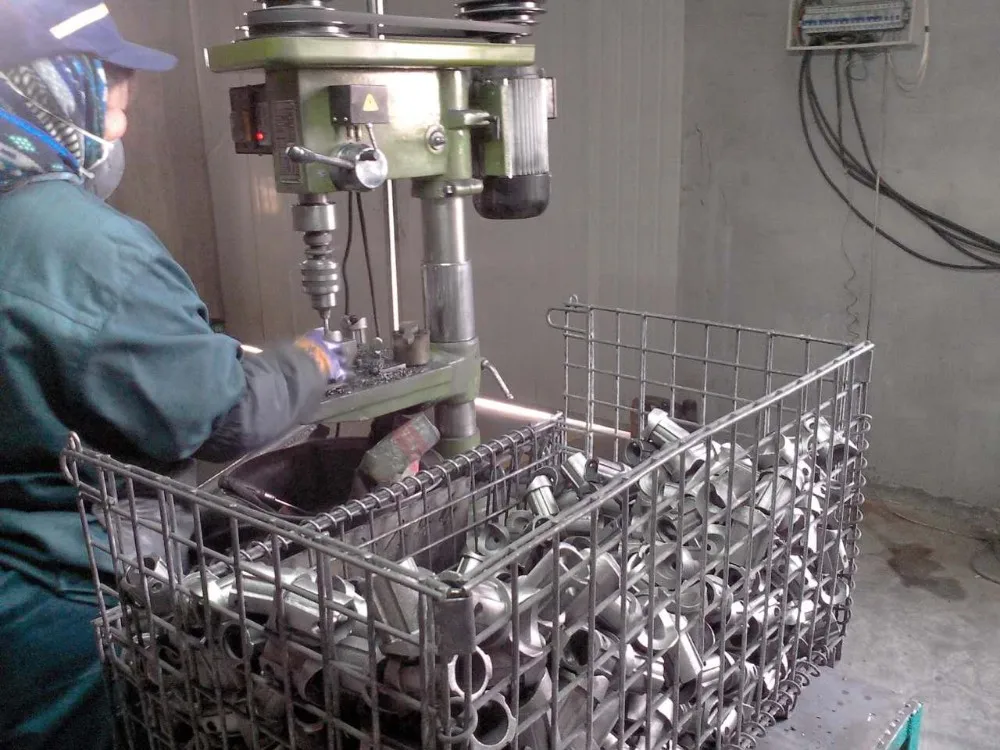

If the casting has hollow sections, a core consisting of hardened sand (baked or chemically hardened) is used. The other half of the mold is produced in a like manner and then the two halves or three parts are positioned together to form the mold. Compaction is achieved by either jolting or squeezing the mold. To produce the mold, usually a metal frame, although wood may be used for some processes and types of castings, is placed over the pattern to produce a cavity representing one half or one part of the casting. The mold material consists of silica sand mixed with a suitable bonding agent “clay” and moisture. The term “green” denotes the presence of moisture in the molding sand and indicates that the mold is not dried. The process uses a mould made of compacted moist sand. Green sand molding is by far the most diversified molding method used in the current casting processes. The ductile iron casting products are widely used for Auto-cars, trains, tractors, trucks, mining machinery components, agricultural machinery parts, textile machinery parts, construction machinery parts, valves and pump parts, etc. Surface treatment process: paint coating, electrophoretic coating, electrogalvanizing coating, black oxide coating, phosphate coating, powder coating, etc.ġ. Machining process: CNC machine, machining center, lathe, mill machine, drill machine, etc.Ħ. Molding machines(we have Z145 Z145 Z148 Z149 molding machines)ĥ.

Hand molding(suitable for small quantity order and complicate structure products) we can produce iron castings from 50 gram to 2000 kilograms Collar Part OEM/ODM Ductile Iron Castings Foundry Metal Components Solution Companyģ. Collar Part OEM/ODM Ductile Iron Castings Foundry Metal Components Solution Companyġ.

0 kommentar(er)

0 kommentar(er)